UNTERNEHMEN

Informieren Sie sich über unsere Kompetenzbereiche und Geschäftsfelder.

KARRIERE

Auf der Suche nach neuen beruflichen Herausforderungen? Besuchen Sie unsere Jobbörse.

SERVICE

Sie erhalten hier Servicedienstleistungen für Pflege, Reparatur und Produktrückssendungen.

KONTAKT

Nehmen Sie Kontakt mit uns auf. Wir helfen Ihnen gerne weiter bei allen Ihren Anfragen.

AKTUELLES

Verpassen Sie keine Neuigkeiten über unsere Produkte, Dienstleistungen und Services.

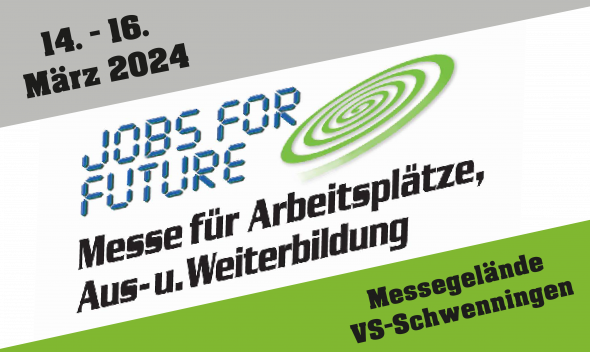

VERANSTALTUNGEN

Schauen Sie auf welchen Kongressen und Messen wir vertreten sind.

Geschäftsfelder

Medizintechnik

In der Medizintechnik positionieren wir uns mit endoskopischen Produktlösungen für die Fachbereiche Laparoskopie, Gynäkologie und Urologie als Technologieführer.

Sowohl mit eigenen Produkten als auch kundenspezifischen Entwicklungen sind wir weltweit auf Erfolgskurs.

Feinwerktechnik

Unsere besonderen Fertigungsfähigkeiten der Rohrbearbeitung nutzen wir auch gezielt für unser Kompetenzfeld Feinwerktechnik. Hier kommen die Erfahrungen und das Know-how direkt unseren Kunden zugute, für die wir zum Beispiel Thermofühler oder Messfühler kundenspezifisch in faszinierender Qualität herstellen.

News & Events

10. – 13. März 2023

38th Annual Congress! EAU23

Halle 3 | Standnummer J37

Mailand, Italien

> Link zu Event